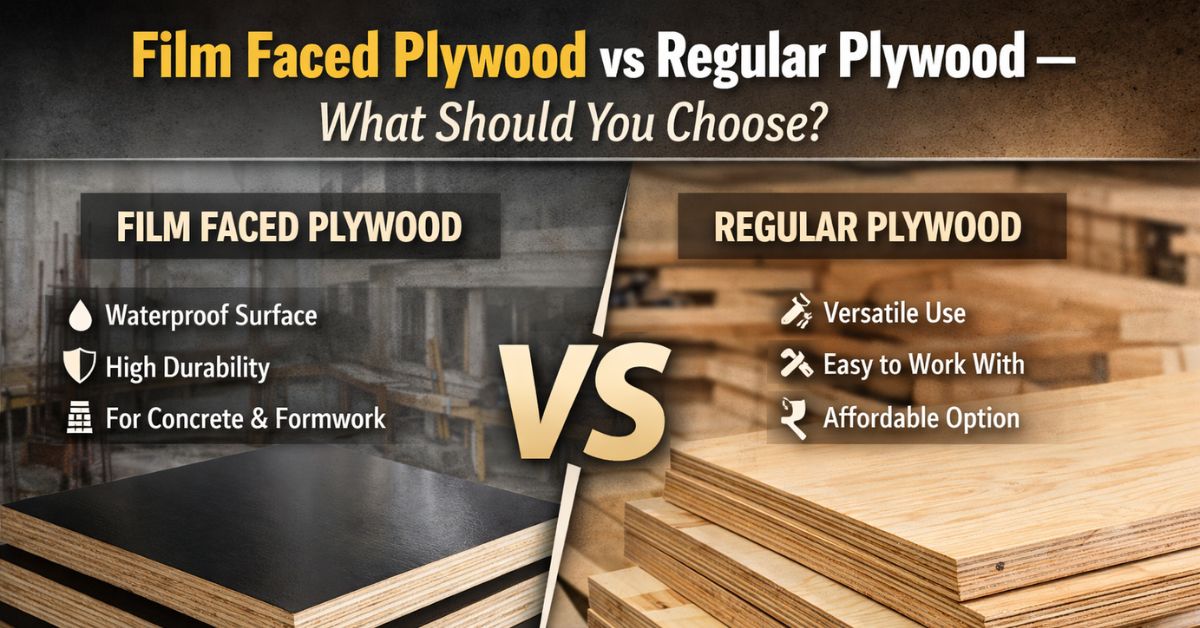

Film Faced Plywood vs Regular Plywood — What Should You Choose?

Choosing the right plywood is not a cosmetic decision. It has an impact on strength, durability, finish quality, and long-term costs. Buyers frequently choose regular plywood because it is familiar. That shortcut usually results in premature damage, higher maintenance and replacement costs. The real choice is between film faced plywood and regular plywood, and the distinction is far more practical than many people realize.

Understanding Regular Plywood: Where It Fits and When It Fails

Under pressure, layers of wood veneer are bonded with adhesive to form regular plywood. It is popular because it is low-cost, widely available, and simple to use.

Where regular plywood works well.

- Interior furniture.

- Decorative panels

- Indoor applications with low moisture levels

- Budget-sensitive residential projects

We break it down clearly and without fluff, so you can choose what works best for your project.

Where it struggled

- Exposure to water or humidity.

- High load-bearing use

- Repetitive use environments, such as construction sites

Regular plywood absorbs moisture quickly. When water enters the core, swelling and delamination start. Even premium grades require surface treatment to withstand harsh environments. This is where its limitations become apparent.

What is Film Faced Plywood and Why Does It Exist?

The film-faced plywood is designed to be durable. It is created by applying a phenolic film to plywood sheets and heat pressing it onto the surface. This film forms a hard, smooth, water-resistant barrier that alters how the plywood performs.

This is why India's film faced plywood manufacturers prioritize construction-grade performance over aesthetics. The product was created to be reused, stressed, and exposed.

Key characteristics:

- Waterproof phenolic film coating

- Core has a high density

- Smooth or anti-skid surface

- Excellent load-bearing capacity

Fundamental Differences Between Film-Faced Plywood and Regular Plywood

1. Resistance to moisture

Water has a negative impact on regular plywood. It is repellent to the film-faced plywood. The phenolic film seals the surface, preventing absorption and significantly extending its lifespan.

2. Capacity and Strength.

Film faced plywood is made with high-quality hardwood cores, making it stronger and more stable. This is important in shuttering, formwork, and other industrial applications.

3. Versatility

In demanding environments, regular plywood is usually only used once. Film faced plywood can be reused multiple times without causing surface damage, lowering long-term costs.

4. Finish the surface.

Film faced plywood provides a clean, uniform finish, making it ideal for concrete formwork applications. Extra finishing work is frequently required for regular plywood.

Why do construction professionals prefer film faced plywood?

There is a reason why contractors prefer film faced plywood manufacturers in India over standard plywood suppliers. The economics are straightforward.

- Quicker project execution

- Reduced material wastage

- Consistent finish on concrete

- Reduced replacement frequency.

Failure is costly in the shuttering and formwork industry. Film faced plywood mitigates this risk.

Quality Standards You Can Expect from Reliable Manufacturers

Not all products labeled film faced plywood perform similarly. Trusted film faced plywood manufacturers in India follow strict guidelines.

Search for:

- High-GSM phenolic film

- Boiling Waterproof (BWP) grade bonding

- Uniform thickness and density.

- A smooth, defect-free surface.

- Certified manufacturing processes

- Inferior products reduce strength and reusability, defeating their purpose.

Environmental and efficiency considerations

Using reusable plywood reduces both timber consumption and material waste. Due to its longer service life, film faced plywood is more compatible with sustainable construction practices.

Many of India's leading film faced plywood manufacturers are now focusing on responsible sourcing and low-emission adhesives, adding an additional layer of value.

Final Thoughts: What Should You Choose?

If your project requires moisture, load, repetition, or outdoor exposure, film faced plywood is the right choice. In such circumstances, standard plywood is a reasonable compromise. The question isn't about which is cheaper today. The real question is which one will avoid failure tomorrow.

That clarity is why professionals consistently choose trusted film-faced plywood manufacturers in India rather than taking chances with standard materials.

Agni Ply manufactures film-faced plywood that meets real-world needs, not marketing claims. Our products are designed to be strong, reusable, and deliver consistent performance across industries. If you want plywood that works as hard as your project does, contact Agni Ply today and make a decision you won't regret.